As the market’s demand for the quantity and quality of high-end electronic products increases, such as mobile phone functions and cameras, optical filters are an important accessory. The hard and brittle nature of optical filters places higher requirements on cutting quality. However, The emergence of laser micromachining equipment provides an ideal solution in terms of quality and efficiency for the processing of ultra-thin glass.

If ultra-thin glass is cut using traditional cutting methods, there will be problems such as high damage rate, low cutting accuracy, limited cutting shape, and environmental pollution. In contrast, ultra-fast precision cutting avoids these problems very well. Laser cutting machines have high precision and efficiency, making them the ideal choice for cutting thin glass.

The main advantages of laser cutting ultra-thin glass technology are as follows:

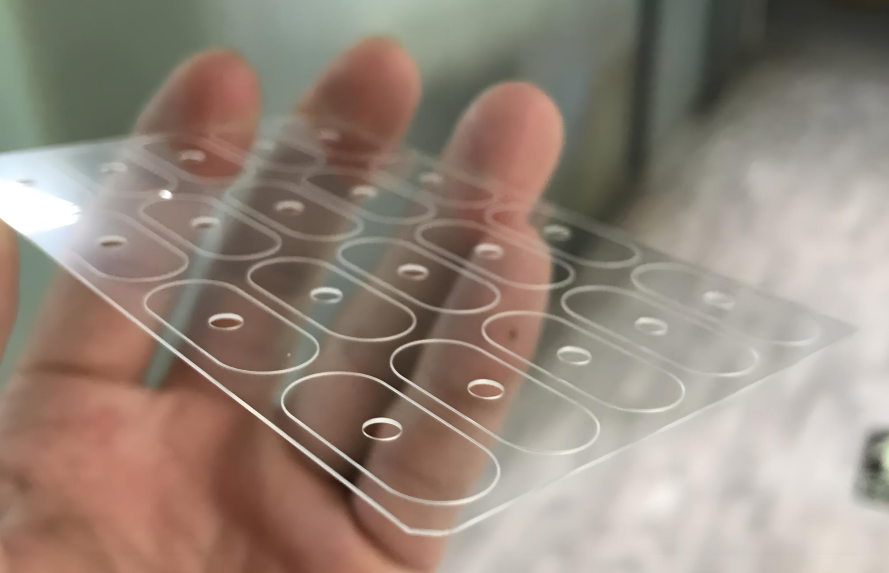

First of all, the use of laser non-contact cutting will not cause stress on the surface of the material, will not turn yellow or black, and avoids the problem of fragility. It can also achieve various special-shaped cutting requirements according to the pattern, and the cutting efficiency is high.

Secondly, the laser cutting spot is easy to control and can be focused to the micron level, meeting high-precision requirements such as fixed-point processing and ultra-fine processing. This makes laser cutting technology have important application prospects in the processing of ultra-thin glass.

Finally, laser cutting is not only highly efficient, but also has a smooth cutting surface, eliminating the need for post-processing and reducing production costs, which is of great significance for improving production efficiency and reducing manufacturing costs.

As laser cutting machine technology is widely used in more and more industries, the market capacity of laser equipment continues to grow, bringing good development momentum to high-end intelligent manufacturing. Not only in the camera industry, but also in other industries such as electronic 3C displays, vehicles, and semiconductor structural parts, manufacturing levels have been improved with the support of laser equipment. The market is enjoying the huge benefits brought by laser micromachining.

As a professional glass laser cutting machine manufacturer, our equipment is widely used in electronic 3C, interventional surgical instruments, semiconductor integrated circuits, automotive parts and other fields. In recent years, due to the increasing demand from customers, our prototype products More and more, it turns out that men-luck’s laser cutting machines are powerful and stable in performance. As long as you have needs, you can provide materials for sample testing.

Post time: Dec-05-2023