With the continuous progress of science and technology, laser micromachining technology has been widely used and rapidly developed in the field of medical devices, and has become one of the important processing methods in the field of medical device manufacturing. Therefore, the processing and manufacturing technology of precision micro-machining laser cutting machine has brought revolutionary changes to the medical device industry with its characteristics of high precision, high quality and strong flexibility.

Precision micromachining laser cutting machines can accurately process shapes in a very small scale range, which is difficult to achieve with traditional processing methods. At the same time, the high energy density of the laser can be used to quickly heat the material above the vaporization point, making it melt or evaporate, so as to achieve precise control of the micro machining structure. This precision machining technology can be used to manufacture various micro-components in medical devices, such as micro-pumps, micro-valves and micro-sensors. Precision micromachining laser cutting machines can also manufacture microstructures such as microholes, microslots and microchannels, which are crucial to the performance and function of medical devices.

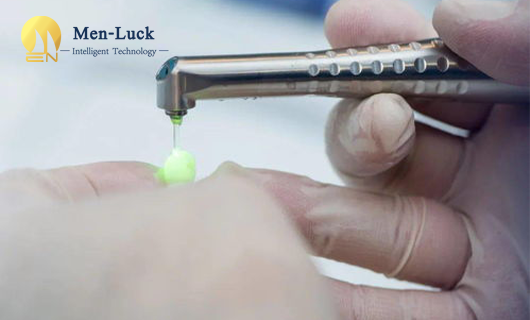

In the field of medical devices, laser micromachining is widely used in the manufacture of various precision medical devices, such as endoscopes, heart stents, micro-cochlear implants and puncture needle tubes. These micro medical devices are often composed of complex structures made of multiple materials and require accurate control of their shape, size and surface quality. Laser cutting machines for laser micromachining can easily handle these complex shapes, and can carry out fine microcarving without damaging the instrument.

In addition, precision micro-machining laser cutting machines can also provide a wider selection of materials for medical devices. Precision micromachining laser cutting machines can be processed using a variety of materials, including metals, ceramics and polymers. These materials have different physical and chemical properties, providing more options for medical device design.

In addition, in the manufacturing process of these micro-parts, the high-precision and high-efficiency precision micro-machining laser cutting machine uses advanced and flexible and diversified parameter adjustment functions, which greatly improves the accuracy of the product on the basis of ensuring product integrity and stability, and effectively solves the difficult problem of complex form parts processing, and significantly reduces the manufacturing cost. Promoted the development of the entire medical device industry.

As a self-developed laser equipment production enterprise, the main equipment includes laser cutting machine, laser welding machine and laser marking machine, providing high-quality system solutions and machine equipment, as well as perfect after-sales service, and support to send samples and proofing, but also welcome customers consultation and field visits.

Post time: Apr-08-2024