Laser surface treatment is a technology that uses high power density laser beam to heat the material surface in a non-contact way, and realizes its surface modification by means of conductive cooling of the material surface itself. It is beneficial to improve the mechanical and physical properties of the material surface, as well as the wear resistance, corrosion resistance and fatigue resistance of the parts. In recent years, laser surface treatment technologies such as laser cleaning, laser quenching, laser alloying, laser shock strengthening and laser annealing, as well as laser cladding, laser 3D printing, laser electroplating and other laser additive manufacturing technologies have ushered in broad application prospects.

1. Laser cleaning

Laser cleaning is a rapidly developing new surface cleaning technology, which uses high-energy pulse laser beam to irradiate the surface of the workpiece, so that the dirt, particles or coating on the surface can evaporate or expand instantly, thus achieving the process of cleaning and purification. Laser cleaning is mainly divided into rust removal, oil removal, paint removal, coating removal and other processes; It is mainly used for metal cleaning, cultural relics cleaning, architecture cleaning, etc. Based on its comprehensive functions, accurate and flexible processing, high efficiency and energy saving, green environmental protection, no damage to the substrate, intelligence, good cleaning quality, safety, wide application and other characteristics and advantages, it has become increasingly popular in various industrial fields.

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

2. Laser quenching

Laser quenching uses high-energy laser as the heat source to make the metal surface hot and cold quickly. The quenching process is completed instantaneously to obtain high hardness and ultra-fine martensite structure, improve the hardness and wear resistance of the metal surface, and form compressive stress on the surface to improve the fatigue resistance. The core advantages of this process include small heat affected zone, small deformation, high degree of automation, good flexibility of selective quenching, high hardness of refined grains, and intelligent environmental protection. For example, the laser spot can be adjusted to quench any width position; Secondly, the laser head and the multi axis robot linkage can quench the designated area of complex parts. For another example, laser quenching is extremely hot and fast, and the quenching stress and deformation are small. The deformation of the workpiece before and after laser quenching can be almost ignored, so it is particularly suitable for the surface treatment of parts with high precision requirements.

At present, laser quenching has been successfully applied to the surface strengthening of vulnerable parts in the automobile industry, mold industry, hardware tools and machinery industry, especially in improving the service life of vulnerable parts such as gears, shaft surfaces, guides, jaws and molds. The characteristics of laser quenching are as follows:

(1) Laser quenching is a fast heating and self-excited cooling process, which does not require furnace heat preservation and coolant quenching. It is a pollution-free, green and environment-friendly heat treatment process, and can easily implement uniform quenching on the surface of large molds;

(2) As the laser heating speed is fast, the heat affected zone is small, and the surface scanning heating quenching, that is, instantaneous local heating quenching, the deformation of the treated die is very small;

(3) Due to the small divergence angle of the laser beam, it has good directivity, and can accurately local quench the mold surface through the light guide system;

(4) The hardened layer depth of laser surface quenching is generally 0.3-1.5 mm.

3. Laser annealing

Laser annealing is a heat treatment process that uses laser to heat the material surface, expose the material to high temperature for a long time, and then slowly cool it. The main purpose of this process is to release stress, increase material ductility and toughness, and produce special microstructure. It is characterized by the ability to adjust the matrix structure, reduce hardness, refine grains and eliminate internal stress. In recent years, laser annealing technology has also become a new process in semiconductor processing industry, which can greatly improve the integration of integrated circuits.

4. Laser shock strengthening

Laser shock strengthening technology is a new and high technology that uses the plasma shock wave generated by strong laser beam to improve the anti fatigue, wear resistance and corrosion resistance of metal materials. It has many outstanding advantages, such as no heat affected zone, high energy efficiency, ultra-high strain rate, strong controllability and remarkable strengthening effect. At the same time, laser shock strengthening has the characteristics of deeper residual compressive stress, better microstructure and surface integrity, better thermal stability and longer life. In recent years, this technology has achieved rapid development, and has a great role in aerospace, national defense and military industry and other fields. In addition, the coating is mainly used to protect the workpiece from laser burns and enhance the absorption of laser energy. At present, the commonly used coating materials are black paint and aluminum foil.

Laser peening (LP), also known as laser shock peening (LSP), is a process applied in the field of surface engineering, that is, the use of pulsed high-power laser beams to generate residual stresses in materials to improve the wear resistance (such as wear resistance and fatigue resistance) of material surfaces, or to improve the strength of thin sections of materials to enhance the surface hardness of materials.

Unlike most material processing applications, LSP does not use laser power for heat treatment to achieve the desired effect, but uses beam impact for mechanical processing. High power laser beam is used to impact the surface of the target workpiece with high power short pulse.

The light beam impacts the metal workpiece, vaporizes the workpiece into a thin plasma state immediately, and applies shock wave pressure to the workpiece. Sometimes a thin layer of opaque cladding material is added to the workpiece to replace metal evaporation. To pressurize, other transparent cladding materials or inertial interference layers are used to capture plasma (usually water).

Plasma produces shock wave effect, reshapes the surface microstructure of the workpiece at the impact point, and then generates a chain reaction of metal expansion and compression. The deep compressive stress generated by this reaction can extend the life of the component.

5. Laser alloying

Laser alloying is a new surface modification technology, which can be used to prepare amorphous nanocrystalline reinforced cermet composite coatings on the surface of structural parts according to different service conditions of aviation materials and the characteristics of high energy density laser beam heating and condensation rate, so as to achieve the purpose of surface modification of aviation materials. Compared with laser alloying technology, laser cladding technology has the characteristics of small dilution ratio of substrate to molten pool, small heat affected zone, small thermal deformation of workpiece and small scrap rate of workpiece after laser cladding treatment. Laser cladding can significantly improve the surface properties of materials, and repair worn materials. It has the characteristics of high efficiency, fast speed, green environmental protection and pollution-free, and good performance of the workpiece after treatment.

Laser cladding technology is also one of the new surface modification technologies representing the development direction and level of surface engineering. Laser cladding technology has become a research hotspot in surface modification of titanium alloys due to its advantages of pollution-free and metallurgical combination between the coating and the substrate. Laser cladding ceramic coating or ceramic particle reinforced composite coating is an effective way to improve the surface wear resistance of titanium alloy. According to the actual working conditions, select the appropriate material system, and the laser cladding technology can achieve the best process requirements. Laser cladding technology can repair various failed parts, such as aeroengine blades.

The difference between laser surface alloying and laser surface cladding is that laser surface alloying is to fully mix the added alloy elements and the surface layer of the substrate in liquid state to form an alloying layer; Laser surface cladding is to melt all the precoating and micro melt the substrate surface, so that the cladding layer and the substrate material form a metallurgical combination and keep the composition of the cladding layer basically unchanged. Laser alloying and laser cladding technology are mainly used to improve the surface wear resistance, corrosion resistance and grading resistance of titanium alloys.

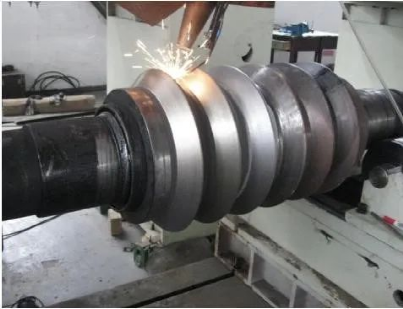

At present, laser cladding technology has been widely used in the repair and modification of metal surfaces. However, although traditional laser cladding has the advantages and characteristics of flexible processing, special-shaped repair, user-defined additive, etc., its work efficiency is low, and it still cannot meet the requirements of large-scale rapid production and processing in some production fields. In order to meet the needs of mass production and improve the efficiency of cladding, high-speed laser cladding technology came into being.

High speed laser cladding technology can realize compact and defect free cladding layer. The surface quality of the cladding layer is compact, metallurgical bonding with the substrate, no open defects, and the surface is smooth. It can not only be processed on the revolving body, but also on the plane and complex surface. Through continuous technical optimization, this technology can be widely used in coal, metallurgy, offshore platforms, paper making, civil appliances, automobiles, ships, petroleum, aerospace industries, and become a green remanufacturing process that can replace traditional electroplating technology.

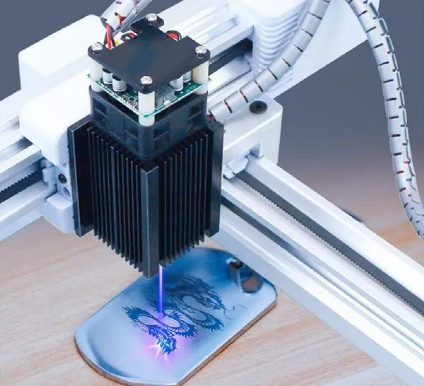

7. Laser engraving

Laser engraving is a laser processing process that uses CNC technology to project high-energy laser beam onto the material surface, and uses the thermal effect generated by laser to produce clear patterns on the material surface. The physical denaturation of melting and gasification of processing materials under the irradiation of laser engraving can enable laser engraving to achieve processing purposes. Laser engraving is to use laser to engrave words on an object. The words carved by this technology have no nicks, the surface of the object is smooth and flat, and the handwriting will not be worn. Its features and advantages include: safe and reliable; Precise and meticulous, the precision can reach 0.02mm; Save environmental protection and materials during processing; High speed, high speed engraving according to the output drawings; Low cost, not limited by processing quantity, etc.

8. Laser 3D printing

The process adopts laser cladding technology, which uses laser to irradiate the powder flow transported by the nozzle to directly melt the simple substance or alloy powder. After the laser beam leaves, the alloy liquid solidifies rapidly to realize the rapid prototyping of the alloy. At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, household appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields.

9. Typical industrial applications of laser surface treatment and remanufacturing

At present, laser surface treatment and additive manufacturing technologies, processes and equipment are widely used in metallurgy, mining machinery, molds, petroleum power, hardware tools, rail transit, aerospace, machinery and other industries.

10. Application of laser electroplating technology

Laser electroplating is a new high-energy beam electroplating technology, which is of great significance to the production and repair of microelectronic devices and large-scale integrated circuits. At present, although the principle of laser electroplating, laser ablation, plasma laser deposition and laser jet are still under research, their technologies have been applied. When a continuous laser or pulse laser irradiates the cathode surface in the electroplating bath, not only can the deposition rate of metal be greatly improved, but also the computer can be used to control the trajectory of the laser beam to obtain the unshielded coating of the expected complex geometry.

The application of laser electroplating in practice is mainly based on the following two characteristics:

(1) The speed in the laser irradiation area is much higher than the electroplating speed in the body (about 103 times);

(2) The control ability of laser is strong, which can make the necessary part of the material precipitate the required amount of metal. Ordinary electroplating takes place on the whole electrode substrate, and the electroplating speed is slow, so it is difficult to form complex and fine patterns. Laser electroplating can adjust the laser beam to micrometer size, and conduct unshielded tracing on micrometer size. For circuit design, circuit repair and local deposition on microelectronic connector components, this type of high-speed mapping is becoming more and more practical.

Compared with ordinary electroplating, its advantages are:

(1) Fast deposition speed, such as laser gold plating up to 1 μ M/s, laser copper plating up to 10 μ M/s, laser jet gold plating up to 12 μ M/s, laser jet copper plating up to 50 μ m/s;

(2) Metal deposition only occurs in the laser irradiation area, and local deposition coating can be obtained without shielding measures, thus simplifying the production process;

(3) The coating adhesion is greatly improved;

(4) Easy to realize automatic control;

(5) Save precious metals;

(6) Save equipment investment and processing time.

When a continuous laser or impulse laser irradiates the cathode surface in the electroplating bath, not only can the deposition rate of metal be greatly improved, but also the computer can control the movement track of the laser beam to obtain the unshielded coating with the expected complex geometry. The current new technology of laser jet enhanced electroplating combines the laser enhanced electroplating technology with the electroplating solution spraying, so that the laser and the plating solution can simultaneously shoot to the cathode surface, and the mass transfer speed is much faster than the mass transfer speed of the micro stirring caused by laser irradiation, thus achieving a very high deposition speed.

Future development and innovation

In the future, the development direction of laser surface treatment and additive manufacturing equipment can be summarized as follows:

·High efficiency – high processing efficiency, meeting the rapid production rhythm of modern industry;

·High performance – the equipment has diversified functions, stable performance and is suitable for different working conditions;

·High intelligence – the level of intelligence is constantly improving, with less manual intervention;

·Low cost – equipment cost is controllable, and the cost of consumables is reduced;

·Customization – personalized customization of equipment, precise after-sales service,

·And compounding – combining laser technology with traditional processing technology.

Post time: Sep-17-2022