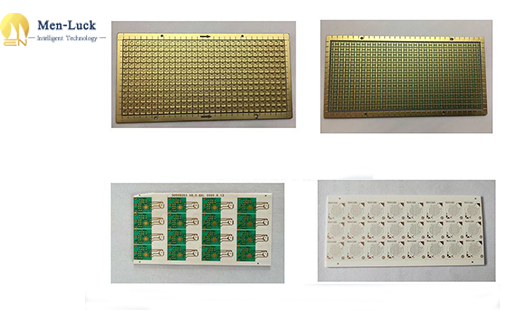

With the development of precision microelectronics, aviation and Marine industry, ceramic substrate circuit board has been widely used. Because the ceramic circuit board uses ceramic material as the substrate, compared with the traditional glass fiber substrate, it has better high-frequency electrical properties, high thermal conductivity, chemical stability and thermal stability. Therefore, when used in high power, high frequency and special environments, ceramic circuit boards can provide more reliable and stable performance. Therefore, ceramics become the ideal basic material for high-power electronic circuit structure and interconnection technology. The use of laser cutting machine processing has become the mainstream.

Because ceramics have high density structure and certain brittleness. Under such high hardness, high strength and brittleness conditions, the traditional cutting processing method is easy to lead to fragmentation when dealing with thin ceramics, which increases the difficulty of cutting and cannot meet the processing needs. Laser cutting machine is a kind of non-contact processing equipment, laser as a flexible, high efficiency, high yield processing method, in the cutting process than the traditional processing method has obvious advantages, especially in the processing of ceramic substrate circuit board shows extraordinary ability.

First of all, the non-contact cutting processing of the laser cutting machine makes the internal stress of the product, the cutting edge is small, the processing accuracy is high, the yield is high, and the heat affected zone is small. Therefore, laser cutting is very suitable for ceramics, which is both hard and brittle materials. Moreover, the gap width formed by laser cutting materials is small, which can save materials. Secondly, the laser spot of the laser cutting machine is small, the energy density is large, which can ensure high-precision cutting, and the incision is smooth and less burrs. Finally, the laser cutting machine has the characteristics of stable processing quality, fast speed and efficiency, which can achieve large-scale and batch processing, suitable for most hard and soft materials, and meet the needs of high density interconnection and fine development of ceramic circuit boards.

men-luck laser cutting machine for ceramics, diamond, tungsten steel and other high hardness and high brittleness material micro-machining developed, not only for the plane laser cutting, but also with the plane, regular surface laser cutting, drilling, grooving, marking and other fine processing technology, but also according to the processing needs of enterprises, to provide high-quality system solutions and equipment configuration.

Post time: Feb-29-2024