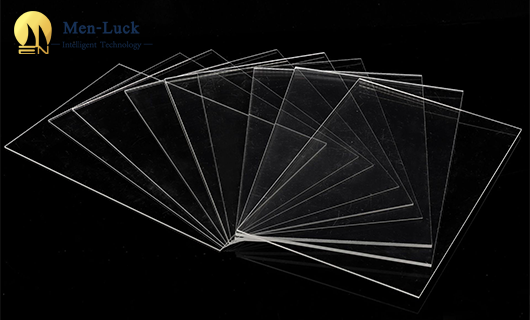

Acrylic, also known as plexiglass, has a light transmittance higher than 92%, while the density is only half that of glass. At the same time, it has the advantages of not breaking, easy dyeing, easy processing and so on. So it is often cut or carved into a variety of shapes, used for handicrafts, dust covers, outdoor billboards and other different purposes. At present, the most ideal processing method is to use carbon dioxide laser cutting machine to cut acrylic, which can not only use precision software system to achieve high-precision automatic cutting processing, but also ensure quality and efficiency. Laser cutting is also one of the most advanced cutting processing methods.

Because the specifications of the acrylic sheet are usually relatively large, it is necessary to use special equipment to cut it to the right size. Under normal circumstances, the hook knife can be used for cutting. When it reaches a certain degree, the acrylic is directly broken manually, but this processing method has the disadvantage of large edge collapse, and further polishing treatment is needed, and the thickness of the plate is required. At the same time, special shapes such as arcs cannot be accurately cut at one time. In addition, blunderbuss cutting can also be used, which can be accurately cut for a specific shape, and obtain good incision effect and high efficiency, but the disadvantage is that there will be a certain loss. Laser cutting machines do not have the above problems.

First of all, the slit processed by the laser cutting machine is narrow, the laser beam is focused into a small spot, so that the focus reaches a high power density, and the material is quickly heated to the degree of gasification and evaporated to form holes. As the light beam moves relatively linearly with the material, the holes continuously form a slit of very narrow width. Secondly, laser cutting uses non-contact processing. The quality of laser cutting is good, the precision is high, the thermal effect is small, the surface of the workpiece is almost no deformation, no yellow black and other problems. Completely avoid the collapsing edge formed when the material is cut, and will not scratch the acrylic surface, and the incision is smooth without burrs. Finally, cost savings. Because laser cutting does not require molds, it saves the cost of mold opening and reduces the production cost, which is especially suitable for the processing of large products. And the acrylic products of different shapes can be cut as a whole acrylic plate to maximize the utilization rate.

After years of development, Men-luck has a complete range of laser processing equipment, including laser cutting machine, laser welding machine, laser marking machine, laser engraving machine and other laser processing equipment. At the same time, men-luck can provide customers with all kinds of laser cutting system solutions and supporting laser processing equipment, and also provide customers with all kinds of sample proof services. Welcome to call to make an appointment!

Post time: Mar-04-2024