In the glass processing industry, the traditional glass cutting method has been with us for a long time. However, with the rapid development of science and technology, glass laser cutting technology has gradually emerged, bringing unprecedented changes to the field of glass processing. I will take you to explore the differences between glass laser cutting machines and traditional glass cutting.

Traditional glass cutters rely on steel wheels for physical cutting and apply pressure to achieve the fracture of the glass. Although this method is simple and practical, it is easy to break the edge and the cutting accuracy and efficiency are low, and the technical requirements for the operator are high, and it is gradually replaced. In contrast, the glass laser cutting machine uses the laser thermal cracking method to induce cracks in brittle materials, guide the crack expansion, and finally achieve the purpose of cutting, and the stress comes from the change of the temperature field formed before and after the laser action in the material. This cutting method does not need physical contact, laser cutting glass has the advantages of fast, effective and non-destructive, only a small power laser irradiation; No slag, straight slit, no material loss; In theory, it can be cut in any shape.

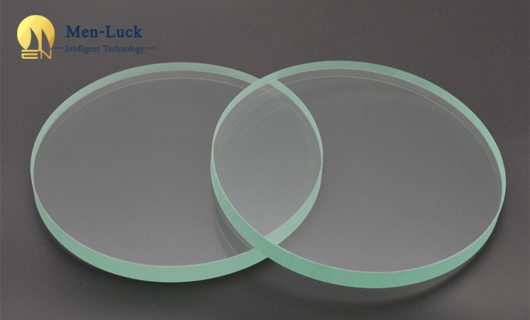

Traditional glass cutting machines may encounter some difficulties when dealing with different thicknesses and types of glass, especially for some special materials of glass, such as reinforced glass, tempered glass, etc., the cutting effect is often unsatisfactory. The glass laser cutting machine has a wide range of material adaptability. It can adapt to various thicknesses and types of glass materials, and can perform fine drilling and engraving work. This makes the glass laser cutting machine in high-end customization, art creation and other fields have greater application potential.

Glass laser cutting machine in the long run, its high efficiency, high precision and low loss characteristics will bring higher economic benefits for enterprises. Especially in mass production and high-end custom markets, the advantages of glass laser cutting machines are more obvious. The rise of glass laser cutting technology is changing the traditional glass processing methods. Compared with traditional glass cutting machines, glass laser cutting machines have higher cutting accuracy, wider material adaptability, more environmental protection and safety, and higher economic benefits. By reducing production costs, improving product quality and meeting individual needs, glass laser cutting machines will help enterprises to stand in the fierce market competition. The main equipment of men-luck is precision medical laser cutting machine, precision hard brittle laser cutting machine, precision alloy laser cutting machine. Support sample proofing, provide high-quality system solutions and equipment, as well as after-sales support services.

Post time: Mar-21-2024