3 Laser flight welding

(1) Principle

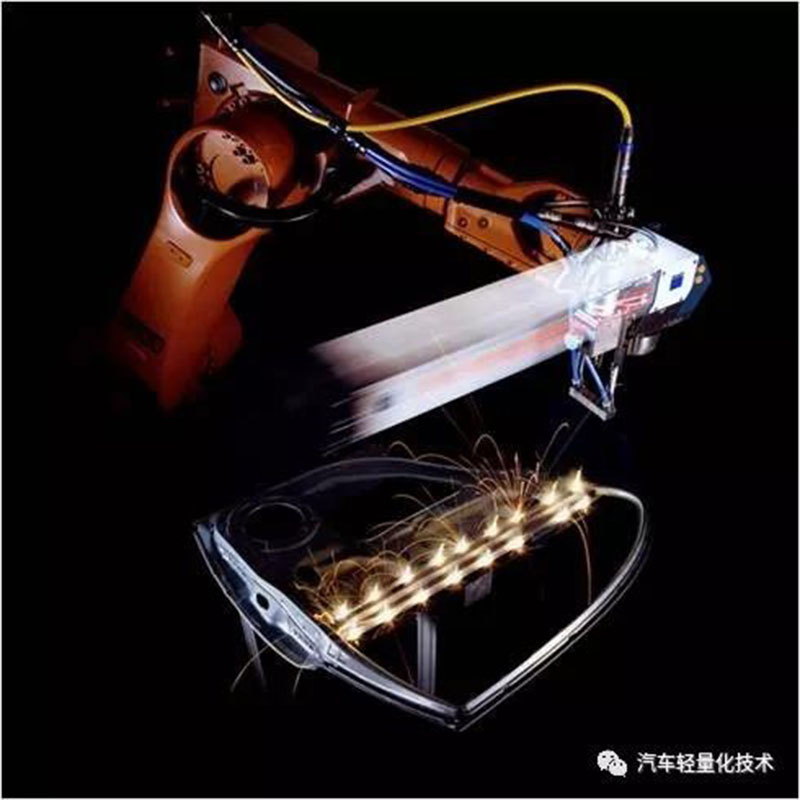

Welding on Fly is called remote laser welding or laser robot scanning welding. It is to install a high-speed scanning mirror scanning head on the sixth axis of the robot, and realize the laser track movement only through the mirror swing reflection, without the robot arm following the movement. The laser remote welding system is highly flexible and more efficient than ordinary laser welding. A set of system can replace 6~9 sets of ordinary robot spot welding. The distance between the laser head and the workpiece exceeds 500mm, which can extend the service life of the lens protection glass. The process principle is the same as that of fusion welding, which is the form of plate lapping. Figure 1 shows that the door is using flight welding.

Fig. 1 Laser flight welding for door welding

(1) Features

Compared with traditional welding, the biggest advantage of laser remote welding is that it can improve production efficiency. The rapid lens movement of the scanning head greatly reduces the time used to locate the manipulator, thereby greatly reducing the manufacturing time. Compared with the average speed of 0.5 welding points/s of resistance spot welding, the welding speed is 3-4 welding points/s, making full use of the laser beam. Through mass production test, compared with traditional resistance spot welding, the time of laser remote welding can be shortened by 80%.

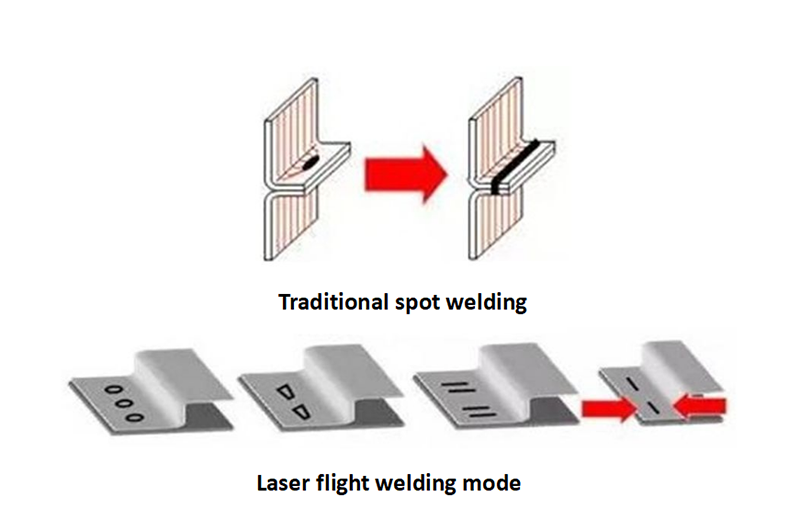

Compared with traditional spot welding, laser flying welding can customize the weld form, optimize the flexibility of weld strength increase design, and can be applied to any weld form and any weld direction. Figure 2 shows the comparison between traditional spot welding and laser flight welding.

Fig. 2 Welding mode of laser flight welding

Fig. 2 Welding mode of laser flight welding

(1) Application area

At present, laser flight welding is mainly used for car doors, side wall door openings and other parts with dense welding points (requiring high welding efficiency) and low load requirements. Figure 3 shows the laser flight welding area of Ford Mustang.

Figure 3 Ford Mustang Interior (a) and Exterior (b)

Figure 3 Ford Mustang Interior (a) and Exterior (b)

For more information, please click:https://www.men-machine.com/news/

Post time: Dec-30-2022