1 Laser brazing

(1) Principle

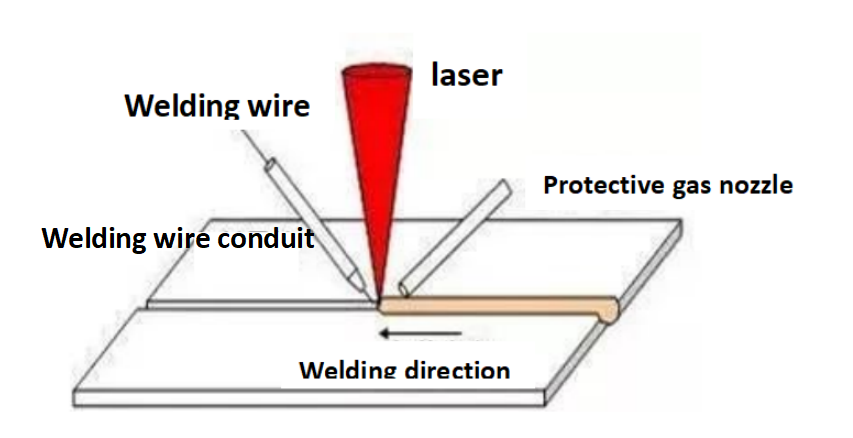

Laser brazing is a welding method that uses laser as heat source, uses materials with lower melting point than the base metal as filler metal (called solder), after heating and melting, uses liquid solder to wet the base metal, fill the joint gap and diffuse with the base metal to achieve connection, as shown in the following figure.

(2) Features

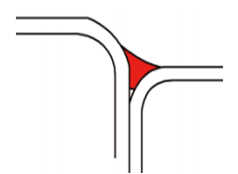

The laser brazing process is applied to welding, which not only makes the product more beautiful and improves the sealing, but also significantly improves the strength of the welding area and improves the safety performance of the vehicle. The base metal connection mode belongs to crimping butt joint, as shown in the figure below.

(3) Application area

Laser brazing is a widely used welding process for automobile body welding at present. Its main advantage is that it can produce smooth surface and avoid melting zinc coating. It is mainly used for: the joint between the side wall outer plate and the top cover outer plate (as shown in Figure 1 and Figure 2, the roof rubber sealing strip is canceled, which is beautiful and cost saving); Joint the upper and lower sections of the trunk lid outer panel (as shown in Figure 3)

Fig. 1 Laser Brazing Appearance of Top Cover

Figure 2 Appearance Comparison of Laser Brazing

Figure 3 Audi Q5 trunk lid

2 Laser fusion welding

(1) Principle

Laser fusion welding is a welding method using laser as heat source to melt part of the base metal of two plates at the corner joint of two plates (at the same time, melt the nearby welding wire to fill the corner joint of two plates) to form liquid metal, and then form a reliable connection after it cools down. Its process principle is shown in Figure 3.

(2) Features

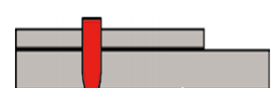

Laser fusion welding can be divided into laser penetration welding, laser fusion welding (without wire filling) and laser fusion wire filling welding. It is mainly used for welding the front end of the car, the top cover and the floor, the inner door panel, etc. The base metal is connected by lapping, as shown in Figure 4.

Fig. 4 Lapping form of laser fusion welding base metal

(3) Application area

Laser fusion welding is mainly applied to roof and door cover. Figure 5 shows the application of laser fusion welding to automobile back door.

Fig. 5 Laser fusion welding for back door welding

For more information, please click:https://www.men-machine.com/news/

Post time: Dec-26-2022