With the process of industrialization in China, people are constantly putting forward higher requirements for the welding quality of hand welding. The traditional argon arc hand welding can no longer meet people's high requirements for welding quality and efficiency.

The standard for measuring the quality of a hand-held welding machine is all sided. On the one hand, it is the welding quality. On the one hand, the machine performance,

1.Welding quality

The welding speed of argon arc welding is slow and easy to produce deformation; The laser hand-held welding is fast, not easy to deform, the weld is very solid, without welding scar, the welding joint is beautiful and smooth, and the performance is stable and reliable.

The company's elite technical talents in the industry are committed to carrying out all-round innovation and iteration on handheld laser welding equipment, promoting the upgrading of welding technology, providing customers with high-quality handheld laser welding equipment, and bringing a new welding experience. The welding speed of laser hand-held welding is 5 to 10 times faster than that of traditional welding.

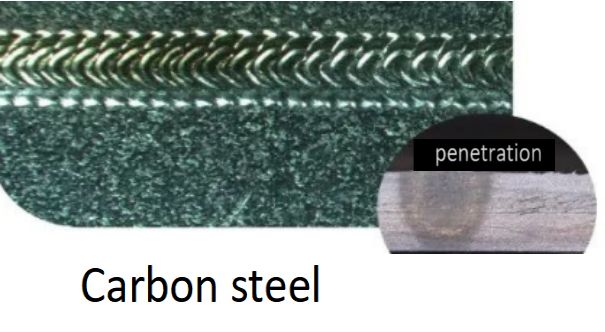

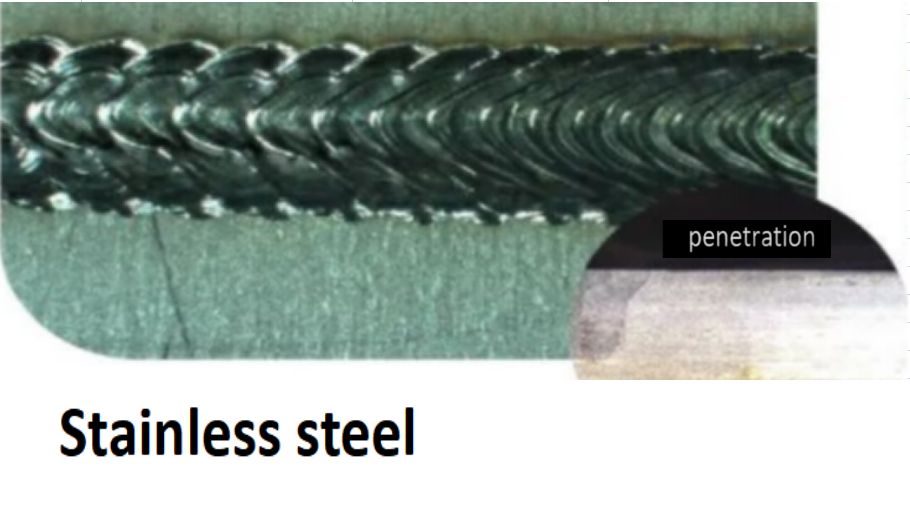

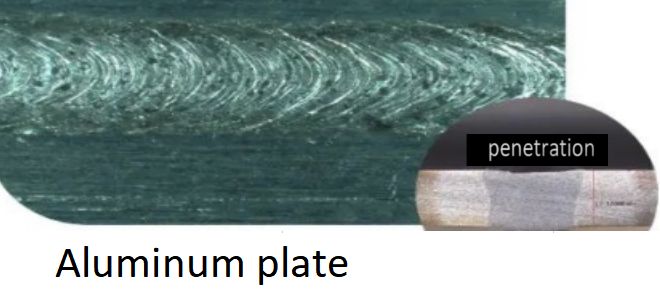

|

Material |

Penetration |

Speed |

|

Stainless Steel |

4mm |

7mm/s |

|

Carbon Steel |

4mm |

6mm/s |

|

Aluminium |

3mm |

7mm/s |

|

Galvanized Sheet |

4mm |

7mm/s |

|

Brass |

3mm |

8mm/s |

|

Copper |

1mm |

8mm/s |

2.Machine quality - layer by layer inspection

Before leaving the factory, each handheld welding machine has passed the 72 hour high temperature (35 ° C) light aging test, and the 12 hour continuous welding 99% power stability test. The laser chip has a service life of 100,000 hours. The product has passed a full set of reliability tests/EMC tests, and is stable and durable.

Post time: Nov-15-2022