welding speed

In the hand-held laser welding operation, the welding speed mainly refers to the speed of the operator moving the welding joint, which is closely related to the laser power, wire feeding speed and other parameters. First of all, neither too fast nor too slow welding speed is allowed. If too fast, the penetration is insufficient, and the welding quality is poor. If too slow, the material may be penetrated. According to the welding power, the uniform movement should be maintained when there is enough penetration.

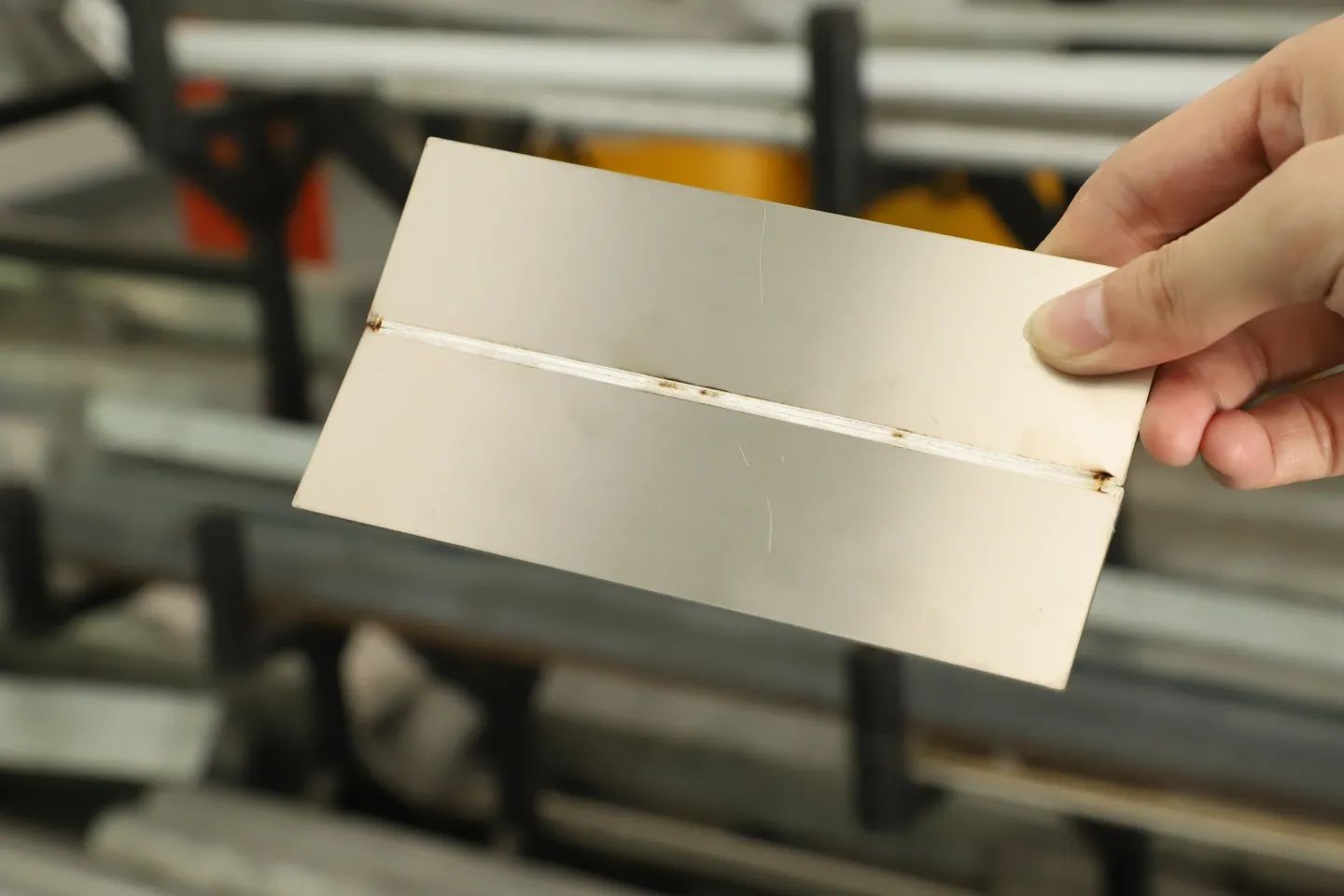

Stainless steel welding

It is reassuring that, although uniform motion seems to be highly demanding, it is easy to find the ideal welding speed by repeated tests in actual operation. Compared with traditional welding, hand-held laser welding is fast and easy to adapt, which is also one of its greatest advantages.

Shielding gas

There are two main functions of shielding gas:

1.Remove the air in the local welding area to avoid oxide film on the material surface;

2.2. Suppress the plasma cloud generated during high power laser welding.

Stainless steel wire less welding

In the actual operation process, the most intuitive effect of shielding gas is the change of weld color. In the process of stainless steel welding, if the pressure of shielding gas is insufficient, or the welding speed is too fast, the gas coverage is not enough, it is easy to cause the weld seam to turn yellow and black, and the aesthetic degree is greatly reduced. Similarly, in order to correctly adjust the shielding gas parameters, basic equipment commissioning is essential. During the commissioning process, attention should be paid to controlling the change of welding speed to avoid multiple problems. What should be paid attention to when doing hand-held laser welding: the weld seam may be yellow because the air pressure is not adjusted properly.

Post time: Jan-30-2023