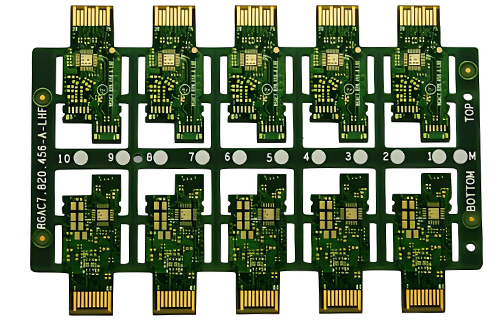

PCB is the abbreviation of Printed Circuit Board. As an important carrier for connecting components, printed circuit boards play a vital role in the electronics industry. With the continuous popularity of electronic products, there is an increasing demand for PCB circuit boards. In the processing of PCB products, laser processing technology, as a high-precision and high-efficiency processing method, has gradually become a necessary processing technology in the industry. Laser micromachining equipment manufacturers introduce laser micromachining technology in detail.

PCB laser cutting is one of the important applications in laser processing. With the continuous development of laser technology, more and more light sources are applied to the PCB industry, such as ultraviolet, green light, optical fiber, CO2, etc. Laser cutting has more advantages than traditional cutting methods: non-contact processing is stress-free and will not make the circuit board black, yellow or deformed; the cutting edge is smooth and neat, without burrs; it can process complex PCBs with components plate.

In addition to PCB laser cutting, laser micromachining also includes laser drilling. Drilling PCB circuit boards with CO2 laser or ultraviolet laser can achieve high-speed drilling of blind holes and through holes, with high efficiency and good processing effects.

FPCA is the abbreviation of Flexible Printed Circuit Assembly. Flexible board cutting has been fully processed by UV laser cutting machines, and has achieved good development momentum in the past two years. At the same time, UV laser cutting machines are also widely used for processing on hard-soft boards.

The application of PCB QR code laser marking is mainly to enhance brand effect and facilitate product quality traceability. Through QR code marking, product management can be facilitated and product market competitiveness can be improved. Laser marking technology has been widely used in the market and has very broad prospects. Depending on the paint surface and material, different types of equipment such as UV laser marking machine, CO2 laser marking machine, fiber laser marking machine, and green light laser marking machine can be used.

The application of laser micromachining technology in the PCB industry has become an important trend in industry development, especially in improving processing accuracy, reducing costs, and improving product quality. With the continuous advancement of technology and the growing market demand, the application of laser processing technology in the PCB industry will be further promoted and deepened, and will bring new opportunities and challenges to the development of the entire industry. As a senior laser micro-machining equipment R&D and manufacturer Changzhou Men-luck, we have complete pre-sales and after-sales services, from proofing, testing, equipment customization, after-sales installation, etc., the service process is standardized, and the equipment quality is first-class. New and old customers are welcome to come to our company to discuss business, and you can also directly make an appointment for proofing services!

Post time: Feb-18-2024