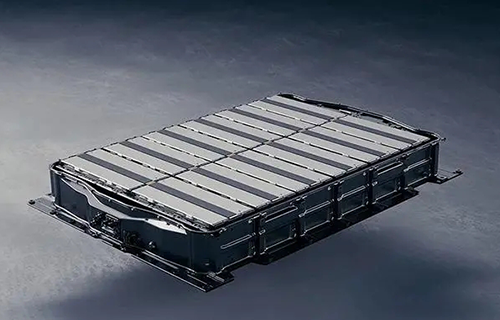

With strong support from national policies and rising international oil prices, more and more people are choosing new energy vehicles, accelerating the rapid development of new energy vehicles. my country’s automobile industry chain is accelerating its transformation towards low-carbonization and electrification, and new materials and new applications are placing higher demands on processing methods. The rational selection of the power battery manufacturing process and cutting process in new energy will directly affect the cost, quality, safety and consistency of the battery.

As a high-precision, high-quality, and efficient processing method, laser cutting technology is of great significance to the manufacturing of power batteries. men-luck will introduce in detail the application of laser cutting in new energy vehicle processing.

The main advantages of laser cutting technology include high cutting precision, good cutting quality, high efficiency and energy saving, etc. Laser cutting uses high-energy laser beams with fine light sources, which can achieve higher-precision cutting and meet the dimensional accuracy requirements in battery manufacturing. Laser cutting can achieve high-quality cutting edges. The cutting surface is vertically smooth, with almost no burrs, no blackening or yellowing, and the material performance of the cutting surface is not affected. Laser cutting uses non-contact cutting, which is better than traditional mechanical knives, so it will not wear out; it will not go empty according to the design drawing, and it is fast, efficient and energy-saving.

Because of the above advantages of laser cutting technology, it plays an irreplaceable role in the manufacturing of power batteries. The main cutting applications of laser cutting machines are as follows:

1. Battery sheet cutting: Battery sheets in power batteries require precise and high-quality cutting to meet the needs of different sizes and shapes. Laser cutting technology can achieve high-precision cell sheet cutting, improving production efficiency and product quality.

2. Electrode plate processing: The positive and negative electrode plates in power batteries need to be precisely processed to meet the requirements of battery components. Laser cutting technology can achieve precise processing of electrode plates and improve the manufacturing quality and consistency of electrode plates.

3. Packaging material cutting: Power battery packaging materials need to be cut accurately to meet the packaging requirements of battery components. Laser cutting technology can achieve high-precision cutting of packaging materials and improve the packaging quality of battery components.

The application of laser cutting technology in the new energy automobile industry is of great significance and plays a key role in precision processing in the power battery manufacturing process. With the rapid development of the new energy automobile industry, the application of laser cutting technology in power battery manufacturing will continue to develop and improve, providing important support for the high-quality development of the new energy automobile industry. As a manufacturer of laser micro-machining equipment, men-luck will also contribute its own efforts in laser cutting technology, making laser cutting machine equipment with higher precision and better quality, and contributing to the better development of the laser industry.

Post time: Dec-22-2023