Precision 3c solution

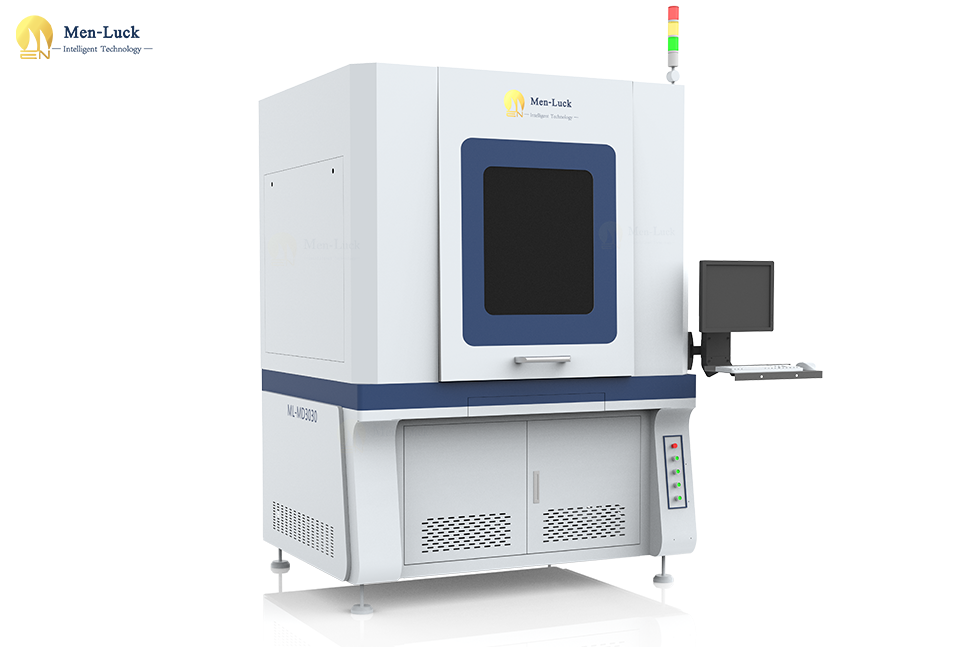

Laser Cutting Machine for Precision Stainless Steel Instruments ML-MD3030

Precision planar instrument microhole laser forming machine

Precision planar instrument microhole laser forming machine is also called precision instrument stainless steel cutting machine. Such as micro-hole forming of aluminum plate, SUS WT micro-hole, blind hole, micro-hole forming of aluminum tube after anode, various hole forming of magnesium-aluminum plate, alloy steel spinneret hole drilling, etc. The equipment has the advantages of small cutting slit width, high processing precision and good cutting quality.

Technical Parameters

| Maximum operating speed | 1000mm/s(X) ;1000mm/s(Yl&Y2) ;50mm/s(Z); |

| Positioning accuracy | ±3um (X) ±3um (Y1&Y2) ;±5um (Z); |

| Repetitive positioning accuracy | ±1um(X) ;±1um (Y1&Y2) ;±3um(Z); |

| Machining material | stainless steel & hard alloy steel & Ceramics & Aluminum & Copper magnesium aluminum alloy |

| Material wall thickness | 0~1.5±0.02 mm; |

| Plane machining range | 300mm*300mm; |

| Laser type | Fiber laser; |

| Laser wavelength | 1030-1070±10nm; |

| laser power | CW100W&200W&300W&QCW150W&450W for option |

| Equipment power supply | 220V±10%, 50Hz;AC 20A (main circuit breaker); |

| File format | DXF、DWG; |

| Dimensions | 1200mm*1300mm*1600mm; |

| Equipment weight | 1200Kg; |

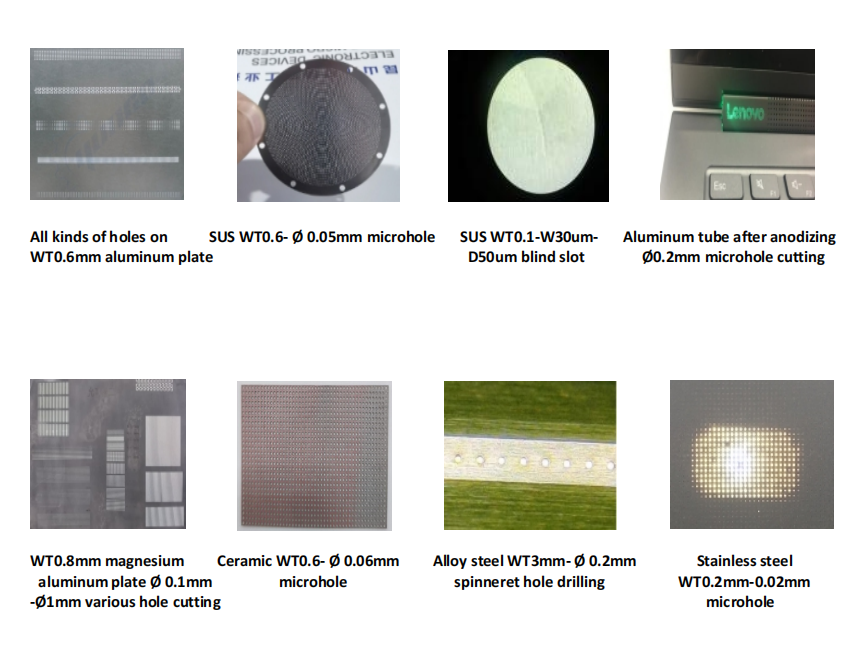

Sample Exhibition

Laser micromachining of precision plane and curved surface instruments of stainless steel & hard alloy steel & Ceramics & Aluminum & Copper & magnesium aluminum alloy

High precision machining

օ Small cutting seam width: 15 ~ 30um

օ High machining accuracy: ≤ ± 10um

օ Good quality of incision: smooth incision & small heat affected zone & less burr

օ Size refinement: the minimum product size is 20um

Strong adaptability

օ Have the ability of laser cutting, drilling, blind slotting, marking and other fine machining technology for plane & curved surface instruments

օ Can machine stainless steel, hard alloy steel, ceramics, aluminum alloy and other materials

օ Equipped with a self-developed direct drive mobile double drive precision movement platform, granite platform, aluminum alloy granite beam for selection

օ Provide the optional function, such as double station & Visual Positioning & automatic feeding and unloading system & dynamic monitoring etc.

օ Equipped with self-developed long & short focal length, sharp nozzle & flat nozzle fine laser cutting head

օ Equipped with modular material receiving and dust removal pipeline system

օ Provide self-developed movable tension frame & fixed tension frame & vacuum adsorption & honeycomb plate, etc. optional fixture

օ Equipped with the self-developed 2D & 2.5D & 3D CAM software system for laser micromachining

Flexible design

օ Follow the design concept of ergonomics, delicate and concise

օ Flexible software & hardware function collocation, supporting personalized function configuration & intelligent production management

օ Support positive innovation design from component level to system level

օ Open control & laser micromachining software system easy to operate & intuitive interface

Technical certification

օ CE

օ ISO9001

օIATF16949

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur