Precision 3c solution

ML-ICP1313 Laser Flatbed Cutting Machine

Introduction to Laser Flatbed Cutting Machine

Laser flatbed cutting machines are mainly used to cut carbon steel plates, ceramic plates, stainless steel plates, iron plates, aluminum plates, magnetic magnetic therapy, etc. with a thickness less than 5mm. Using non-contact laser cutting, the cutting precision is high and the speed is fast. The incision is not affected by mechanical stress and has no quality problems such as yellowing or blackening. The cutting surface is smooth and burr-free, and no processing or processing is required.

Advantages of laser flat cutting machine

The men-luck laser flatbed cutting machine uses a single-mode continuous fiber laser, which has high photoelectric conversion efficiency, good beam quality, and strong Congo reflection ability; it is equipped with a high-precision ball screw module, efficient and precise transmission, simple maintenance, and smooth operation; gantry type The motion module is suitable for large-format flat panel processing. The accordion-type dust cover effectively prevents dust from entering, making maintenance simple and convenient;

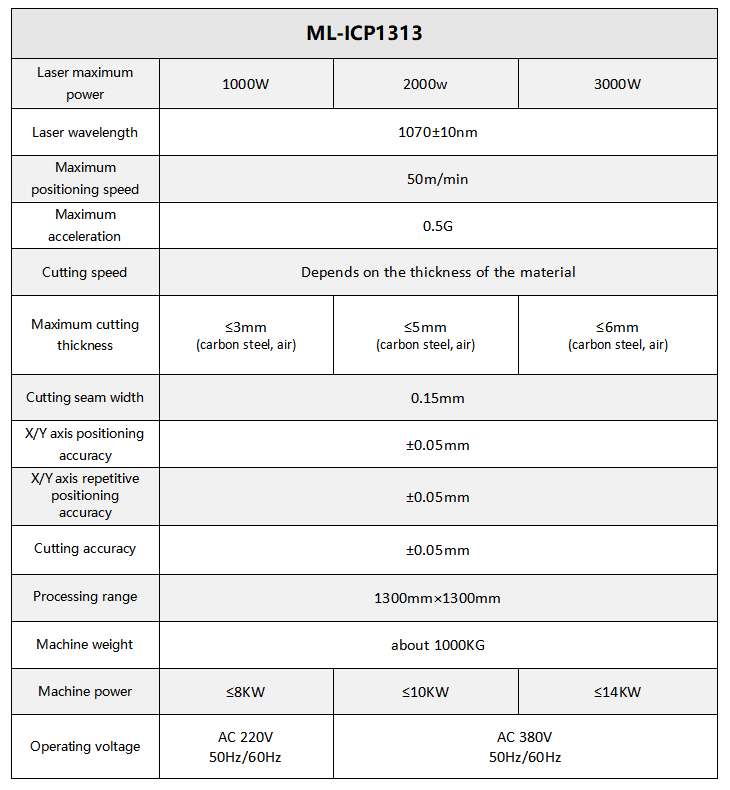

Laser flat cutting machine parameters

Laser flat cutting machine sample

Men-luck, a laser microprocessing equipment manufacturer, has maintained long-term cooperation with famous laser optics manufacturers in the United States and Europe, and has always maintained friendly and close communication with new and old customers. After years of accumulation in R&D, production, sales and service, we have continuously improved our equipment and technology. We have carried out upgrades and improvements to make laser micromachining equipment more precise and of better quality, and we have always been at the forefront of the industry. At present, our laser equipment has stable performance and high cost performance. It has passed 3C certification, so you can buy it with confidence!

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur