Industry Laser Eqipment

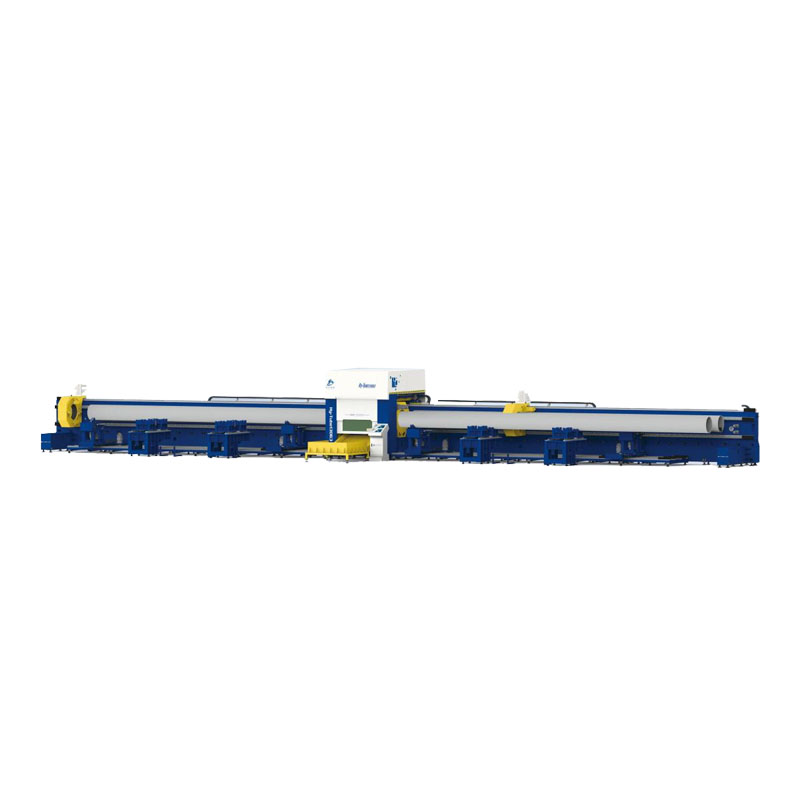

MEN-SK6022 Three Chuck Professional Pipe Laser Cutting Machine

MEN Three Chuck Professional Pipe Laser Cutting Machine, is customized for customers with special requirements. It adopts long-term stable and reliable famous brand fiber laser, and is equipped with high-precision gear and rack, imported high-precision linear guide rail and other high efficient transmission parts. It is a high-tech product integrating the latest laser cutting, precision machinery, numerical control technology and other disciplines. The three-chuck laser pipe cutting machine adopts multi chuck clamping mode, can realize material reversing cutting. When the two-chuck laser pipe cutting machine is working, part of the tailings can not be cut, which resulting in material waste. While the three-chuck can realize "zero tailing", so as to improve the utilization of materials and save costs.

The machine has very low operation and maintenance costs to meet the needs of 24-hour industrial production requirement. It is a real pipe cutting expert. The bus CNC system based on Windows operating system has the advantages of fast response, low failure and less maintenance. The special platform for laser pipe cutting machine integrates the special function module for laser cutting control, with powerful function, good man-machine interface and simple operation. The professional pipe cutting software is one of the core technologies of CNC pipe cutting machine to achieve "full-time & efficient cutting", which is the fundamental guarantee to effectively save materials and improve cutting efficiency.

MEN-SK6022 adopts automatic centering chuck, which has the function of automatic adjustment center, and can realize fast centering and clamping. At the same time, the clamping force can be automatically adjusted to ensure that, there is no deformation of the thin-walled pipe, no throwing off of the thick-walled pipe, and no scratch of the coating pipe. The tail of the rear chuck suctions, the front chuck side suctions, the inner wall of the cutting workpiece is cleaner, and the dust and smoke in the cutting area can 95% eliminated. The cutting section of pipe is smooth and free from burr, slag, black and yellow. It can easily realize the cutting, perforation and pattern cutting of round pipe, square pipe and oval pipe of various metal materials, and can also process channel steel, angle steel, I-beam and other profiles, so as to meet the needs of multi projects running at the same time, and improve the flexibility of factory production. Vertical bed is more convenient for automatic loading and unloading of heavy pipe and large pipe. With the automatic loading and unloading system, 4 tons of material can be loaded at one time, eliminating the frequent use of manpower and forklift, improving work efficiency; automatic unloading, the whole process does not need staff operation, helping the factory to realize automation and intelligence, reduce the number of operators and improve processing efficiency at the same time. The automatic identification system of pipe cross section makes it possible to mix and load various pipes, automatically prompt the type of pipe, automatically retrieve technology library data, and prompt the optional processing program. At the same time with HY customized capacitive sensor swing cutting head, high induction precision, sensitive response, the most stable and reliable performance, can achieve the best cutting effect.

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur