Medical device solutions

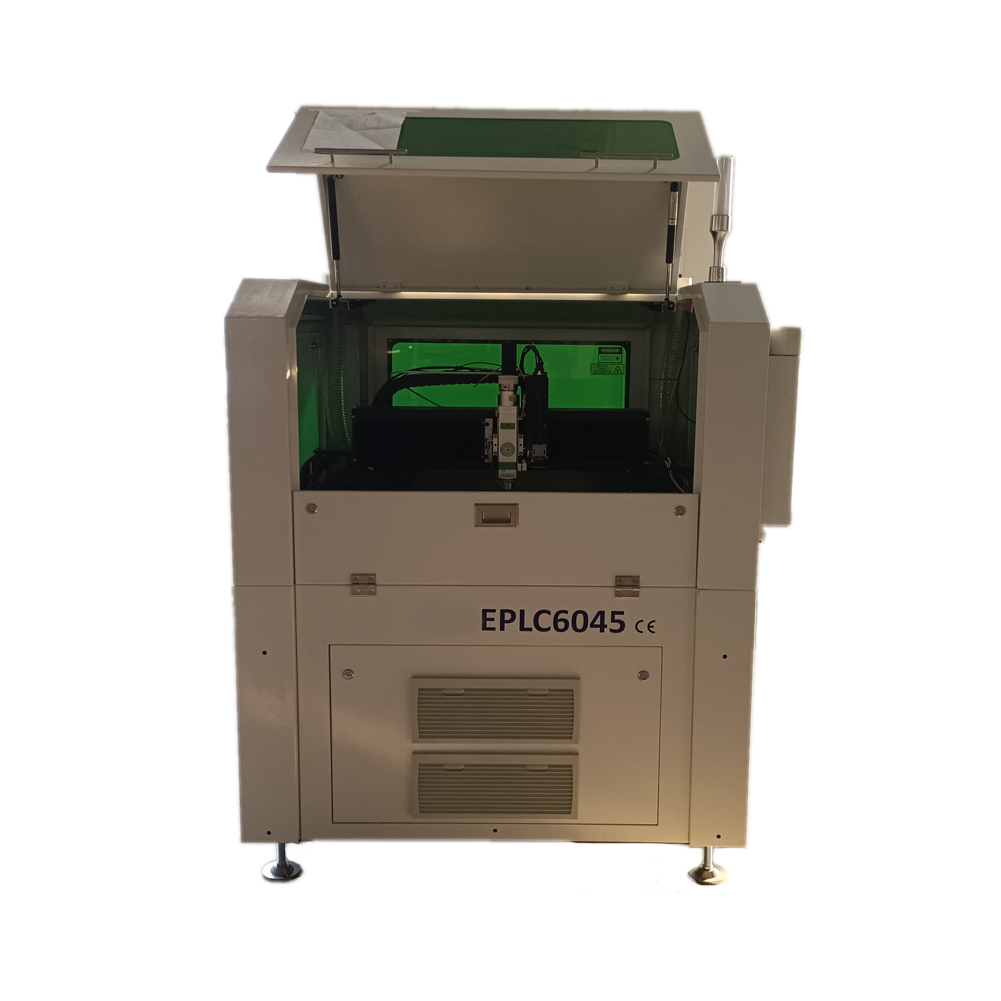

Laser Cutting Machine for Medical Planar Instruments MPLC6045

Technical Parameters:

| Maximum Operating Speed | 300mm/s(X1);100mm/s(X2);50mm/s(Y);50mm/s(Z);600rpm(θ) | |||

| Positioning Accuracy | ±3um(X1);±5um(X2);±3um(Y); ±3um(Z);±15arcsec(θ) | |||

| Repetitive Positioning Accuracy | ±1um(X1);±3um(X2);±1um(Y);±1um(Z);±3arcsec(θ) | |||

| Cutting Seam Width | 20um~30um; | |||

| Machining material | 304&316L&Ni-Ti&L605&Al&Gu&Li&Mg&Fe etc. | |||

| Tube blank length | < 2.5m (support fixture can be customized); | |||

| Processing wall thickness | 0~1.5±0.02 mm; | |||

| Pipe processing range | Φ0.3~Φ7.5&Φ1.0~Φ16.0±0.02 mm; | |||

| Plane processing range | 200mm(300mm)*100mm; | |||

| processing range | 0~300mm&0~600mm (longer products can be processed by segmented splicing method); |

|||

| Length of surplus material | 60mm; | |||

| Laser type | Fiber laser; | |||

| Laser wavelength | 1030-1070±10nm; | |||

| laser power | 200W&250W&300W&500W&1000W&QCW150W for option; | |||

| Equipment power supply | 220V± 10%, 50Hz;AC 25A (main circuit breaker); | |||

| File format | DXF&DWG&STP&IGS; | |||

| Equipment dimensions | 1200mm(&1800mm)x1300mmx1750mm; | |||

| Equipment weight | 1500Kg; | |||

EPLC6045

Strong adaptability

①With laser dry cutting & wet cutting & drilling & slotting and other fine machining capabilities

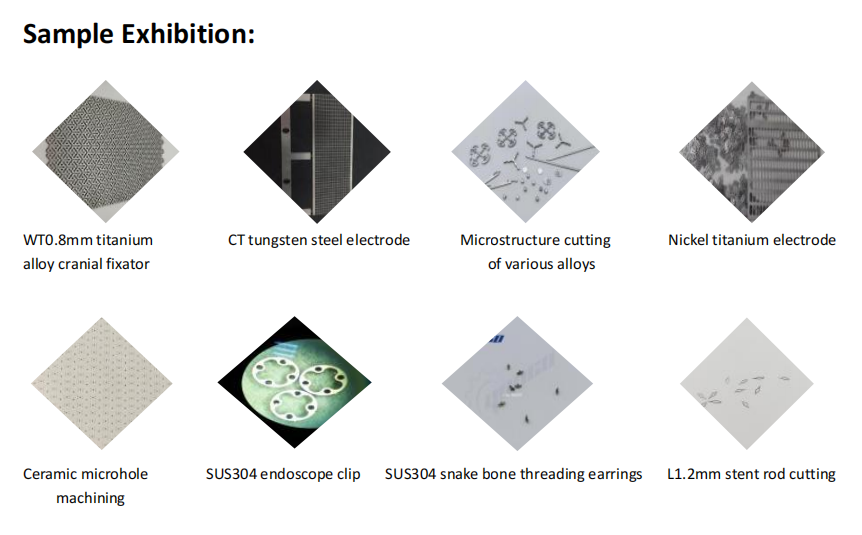

②Can machine 304&316L&Ni-Ti&L605&Li&Mg&Al&Cu&Fe&Ceramic and other materials

③Can machine plane and curved surface instruments

④Provide double position & machine vision positioning & receiving and closed blanking & automatic loading and unloading system & machining dynamic monitoring and other matching functions

⑤Equipped with self-developed long & short focal length fine laser cutting head with sharp & flat nozzle & compatible with commercially available laser cutting head

⑥Equipped with self-developed 2D & 2.5D & 3D CAM software system for laser micromachining

Follow the design concept of ergonomics, delicate and concise

Application scope:

Laser micromachining of surgical and orthopedic instruments such as rigid endoscope & ultrasonic scalpel & endoscope& stapler & suture device & soft drill & planer & puncture needle & nose drill

High precision machining:

①Small cutting seam width: 18~30um

②High machining accuracy: ≤ ± 10um

③Good quality of incision: no burr & smooth incision

④High machining efficiency: one-off cutting through one side tube wall & continuous automatic feed machining

Flexible design

①Follow the design concept of ergonomics, delicate and concise

②Provide the optional function of machine vision system to real time online monitor the laser dynamic machining process

③The software and hardware functions match flexibly, support personalized function configuration & intelligent production management

④Support forward innovative design from component level to system level

⑤Open type control & laser micromachining software system is easy to operate & intuitive interface

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur